Product Description

Product

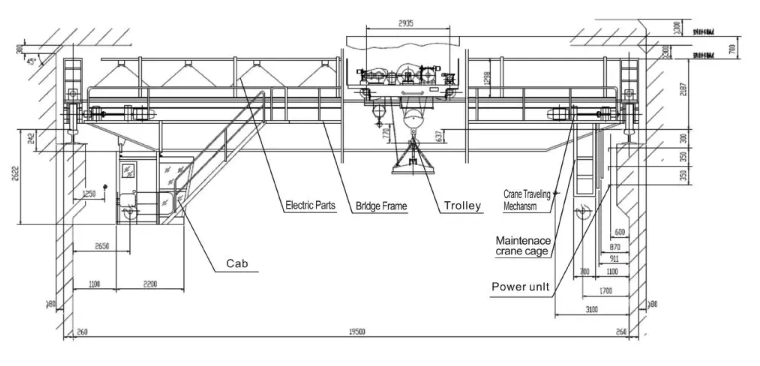

Double Girder Overhead Crane with Electromagnet is a specialized crane for lifting and moving steel products, steel plates and steel pipes. This crane is constituted by girder, traveling mechanisms, lifting trolley, electric parts and electromagnet spreader. The electromagnetic suction force of this overhead crane can last 10 minutes after power off. And the shape of electromagnet spreader could be customized bases on the shape of materials to be lifted.

There are 2 types of electromagnet spreader: electromagnetic chuck and electromagnetic beam. And electromagnetic beam can also be 2 kinds: non-rotating beam (vertical or parallel to main girder) and rotating beam (Upper beam or hanging beam).

Features

1

Three kind entrances to the cab: end, side and top entrances;

2

The rotating part of hook must be locked by screws during electromagnetic plate working;

3

Its lifting capacity includes the weight of electromagnetic part, and the weight of whole crane does not include the weight of electromagnetic chuck and its components;

4

Box-typed girder structure is welded in high strength by robots;

5

Wheels, winding drums, gears and couplings are manufactured by CNC with best quality;

6

Heavy-duty slip ring motor from Wuxi NGP, the best quality in China;

7

Electric equipment from German Siemens

8

Independent control system: wireless control or cab control;

9

Lifting overload protection device;

10

Polyurethane buffer;

11

Crane travel limit switch;

12

Decompression protection;

13

Emergency shutdown device;

14

Current overload protector.

01

Beam

1.Steel plate material Q235B/Q345B;

2.CNC cutting for complete steel plate,

With high surface flatness and accuracy;

3.Epoxy zinc-rich painting,2*2 with 140μm.

02

Electromagnet

1.Lifting material :case ingot,steel scraps,steel ball,steel billets;

2.Widely use in steel plants,melting plants,waste warehouse,billet processing plants;

3.High working efficiency,safe and reliable operation

03

Cabin

1.Open and closed;

2.High-strength frame;

3.The decoration is made of medium density board and aluminum plastic plate or with thin steel plate riveting.

04

Trolley

1.Final drives gears are made with heat-treated carbon steel offering greater strength;

2.Precision needle bearing used in high-load areas offers lower friction level and longer life;Safety durable hook keep the loads.

05

Wheel

Equipped with high quality forged or casting wheel,which will have heat treatment to ensure wheel’s performance.

06

Motor

The motor for electric hoist lifting and traveling crane.

Technical Parameters

|

Lifting capacity(t) |

16/3.2 Main hanger Electromagnetic |

20/5 Main hanger Electromagnetic |

32/5 Main hanger Electromagnetic |

20/5 Aux hanger Electromagnetic |

32/5 Aux hanger Electromagnetic |

||

|

Span(m) |

10.5-31.5 |

||||||

|

Lifting height |

16/18 |

12/14 |

16/18 |

14 |

|

||

|

Working class |

A6 |

||||||

|

Speed (m/min) |

lifting |

Electromagnetic |

13 |

12.6 |

9.5 |

15.6 |

15.6 |

|

Aux.hook |

14.6 |

15.5 |

15.5 |

9.8 |

9.5 |

||

|

Trolley traveling |

44.6 |

44.6 |

43.4 |

44.6 |

42.4 |

||

|

Crane traveling |

76/89 |

76/89 |

89/75.3 |

76/89 |

89/75.3 |

||

|

Power supply |

380v,50HZ,3phase or customized design |

||||||

Configuration

Related Product

-

.jpg) Overhead CraneOverhead Crane mainly consists of single main beams, end beams, hoist, electrical parts and other components. Overhead cranes are used for lifting heavy objects in industrial production, metallurgy, warehouses, construction, mining and other industries.

Overhead CraneOverhead Crane mainly consists of single main beams, end beams, hoist, electrical parts and other components. Overhead cranes are used for lifting heavy objects in industrial production, metallurgy, warehouses, construction, mining and other industries. -

LD-Single Girder Overhead CraneSingle Girder Overhead Crane is a light equipment of crane. It is widely used in plants, warehouses, material stocks to lift goods.

LD-Single Girder Overhead CraneSingle Girder Overhead Crane is a light equipment of crane. It is widely used in plants, warehouses, material stocks to lift goods. -

.jpg) LX-Suspension Overhead CraneIt is applicable for factories and warehouses where the height from the rail surface to the lower edge of the truss is equal to or shorter than 500mm.

LX-Suspension Overhead CraneIt is applicable for factories and warehouses where the height from the rail surface to the lower edge of the truss is equal to or shorter than 500mm.

Request A Quote

Get in touch with our overhead crane experts by calling us or filling in this contact form.

English

English

Spanish

Spanish

Russian

Russian